Hi,

first of all, I would like to say thanks to the development team for their Proview, support and inspiration!

Parallel with this post, we present some specific applications in the Project Forum that helped to create the first industrial controller which directly supports the Proview.

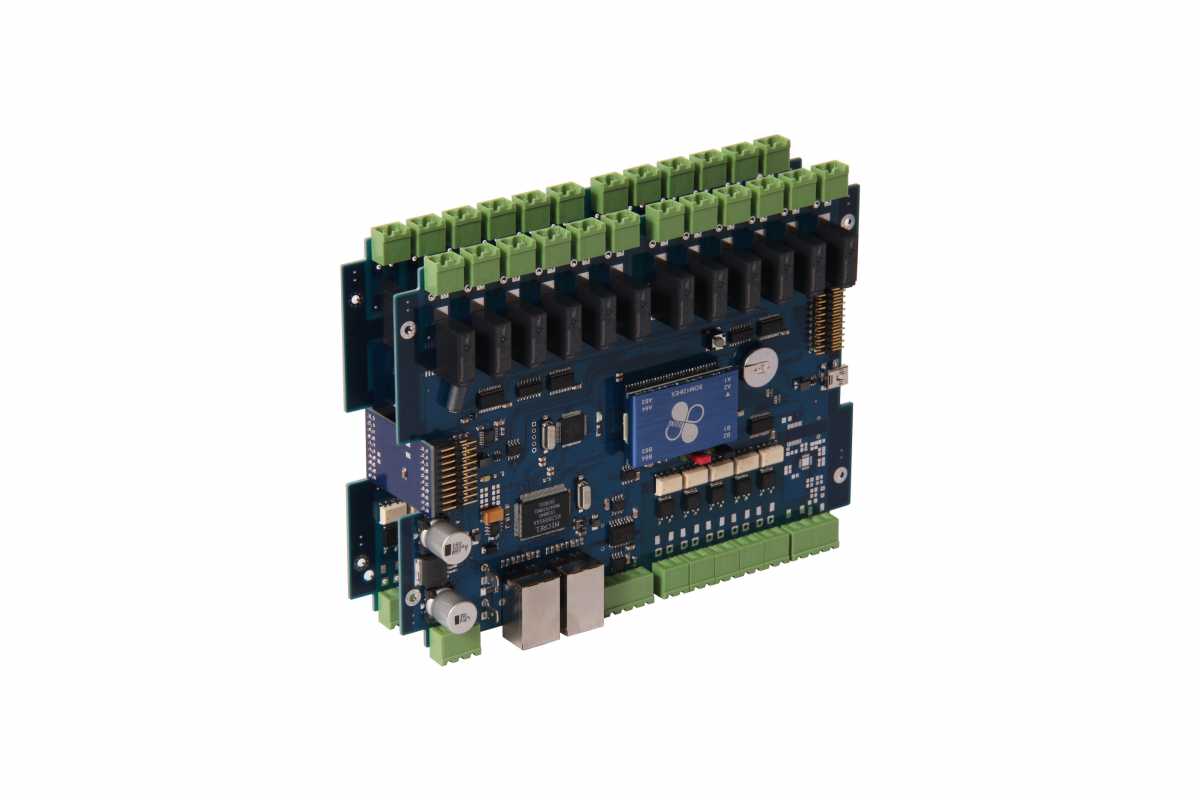

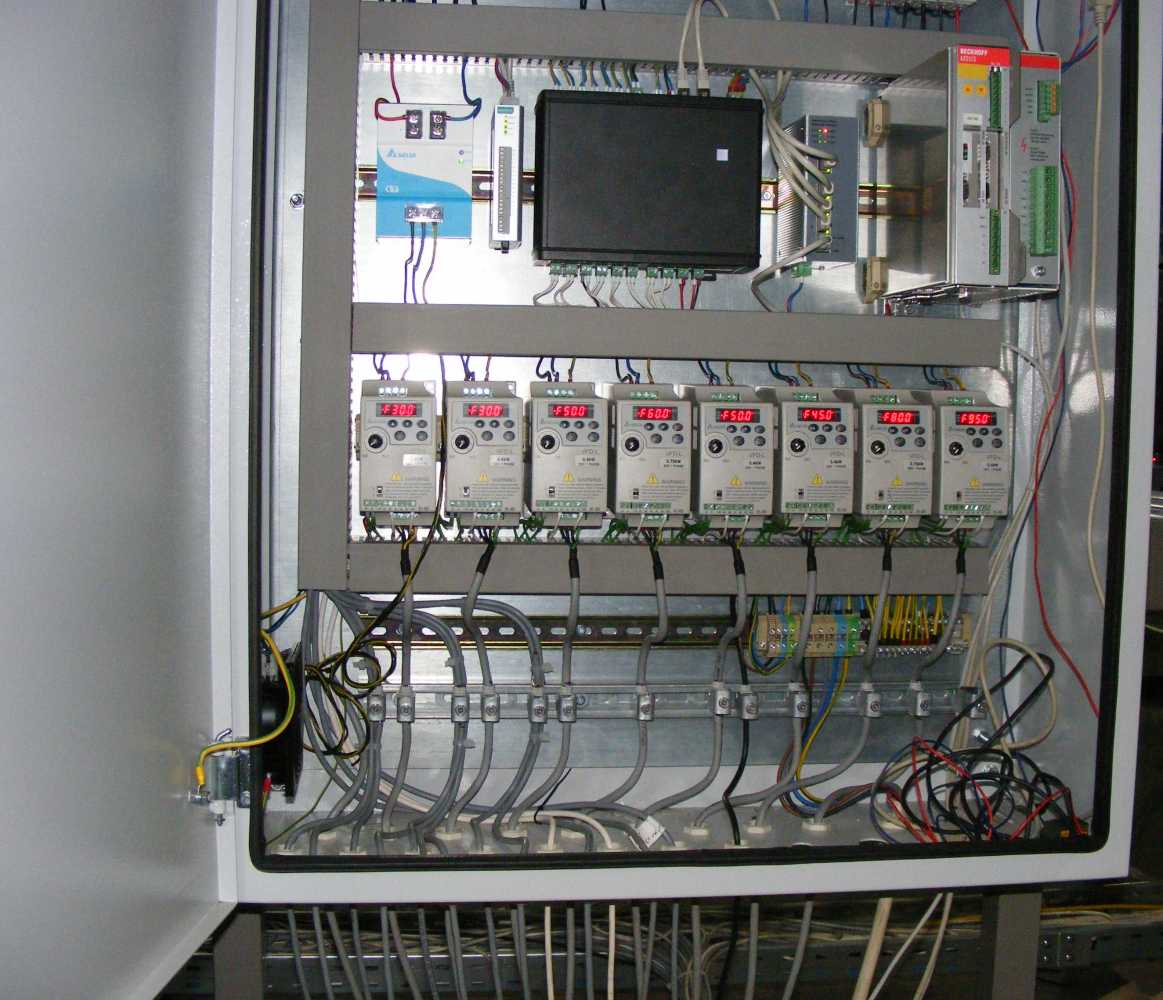

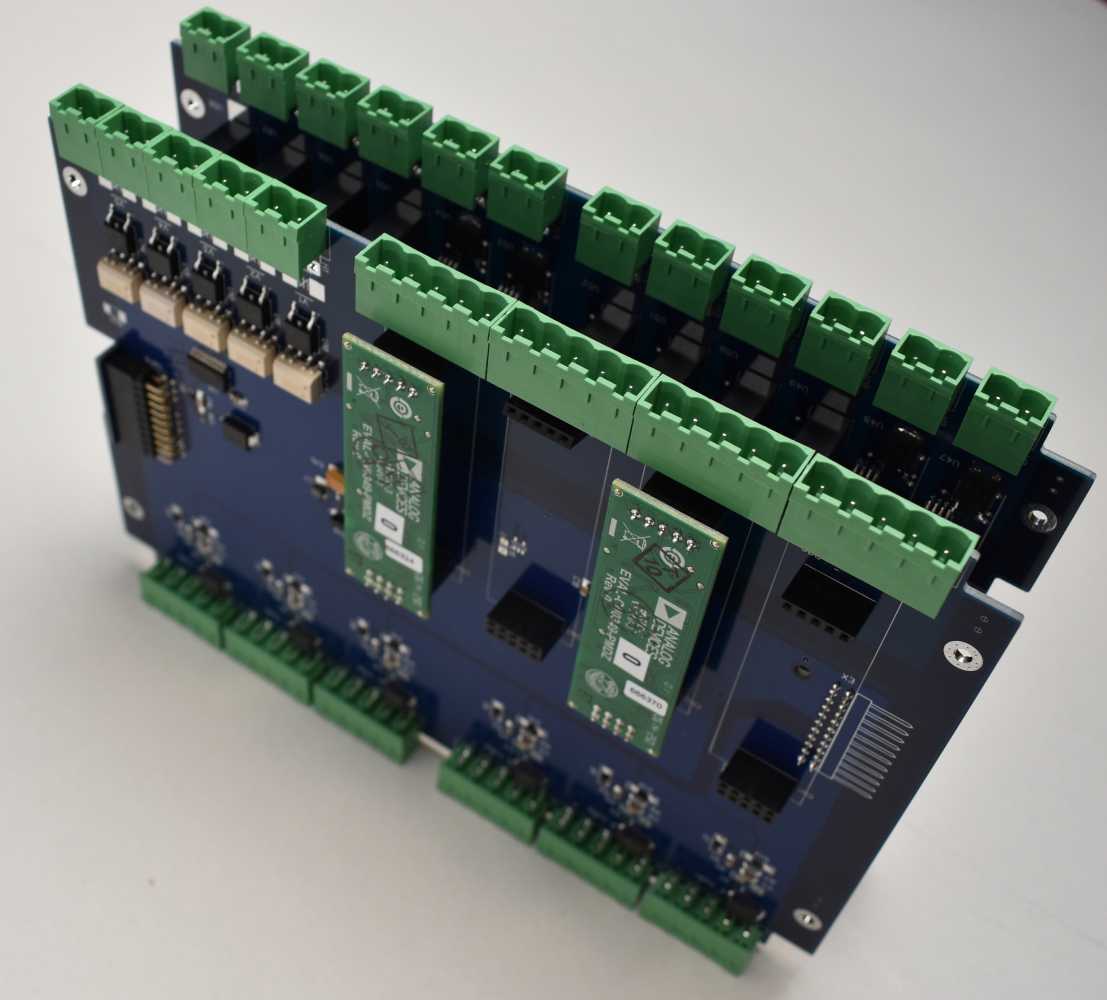

The development of our caLC controller family has been completed and ready for production!

Our caLC (Computerized Adaptive Logical Controller) system is based on the

concept of combining the traditional and robust PLC hardware with the flexibility

and the wide range of application possibilities of the computers. We realized our

goals by designing a highly reliable I/O system which is built around an industrial

computer. The result of our development is a compact and scalable system,

which is adjustable according to the needs of the application.

If you have any questions regarding the details our controller feel free to ask.

Regards

Miklós